|

| July 28, 2015 | Volume 11 Issue 28 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New honeycomb-inspired design delivers superior impact protection

Researchers in the Cockrell School of Engineering at The University of Texas at Austin have developed a groundbreaking new energy-absorbing structure to better withstand blunt and ballistic impact. The technology, called negative stiffness (NS) honeycombs, can be integrated into car bumpers, military and athletic helmets, and other protective hardware.

The technology could have major implications for the design and production of future vehicles and military gear to improve safety.

The new NS honeycomb structures are able to provide repeated protection from multiple impacts, offering more durability than existing honeycomb technology found in a range of products from automobiles to aircraft. The UT Austin team's research on the innovative structure was published online in Integrated Materials and Manufacturing Innovation in May.

"Whether you're serving our country in uniform, playing in a big game, or just driving or biking to work, the potential for multiple collisions or impacts over time -- however big or small -- is a reality," said mechanical engineering professor Carolyn Conner Seepersad. "We believe that this technology, when constructed in future helmets and bumpers, could reduce or even prevent many of the blunt-force injuries we see today."

Seepersad led the work along with UT Austin research scientist Michael Haberman.

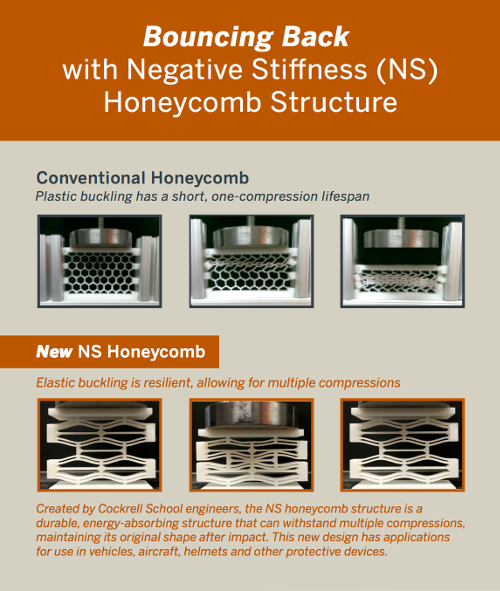

Conventional honeycomb structures are insular panels of repeating, often hexagonal-shaped cells in a range of sizes and configurations. The shortcoming of conventional honeycombs is that they lose their full protective properties after only one impact due to plastic buckling of the material. This means that after absorbing the force of one compression, they do not return to their original shape.

NS honeycombs, on the other hand, bounce back.

The researchers devised a cell geometry capable of elastic buckling, giving NS honeycomb structures the resilience to recover their energy-absorbing shape and properties after impact.

The cell dimensions can be customized to withstand different amounts of force, translating to a variety of versatile applications. The current 3.5-in. lab prototype, for example, has a force threshold level of 200 newtons -- capable of absorbing the energy of a 100-mph fastball in 0.03 seconds.

The researchers manufactured 3.5-in. NS honeycomb structures, as well as miniature NS honeycomb cells, from nylon using selective laser sintering for experimentation. (NS honeycombs can be made from a variety of materials to suit distinct applications.) Subsequent custom compression and drop tests, designed and fabricated at UT Austin, have confirmed the NS honeycomb structures' predicted energy-absorbing behavior and resilience.

Video: A demonstration of a negative stiffness (NS) honeycomb showing elastic buckling.

In 2014, the research team received a Small Business Innovation Research Grant from the U.S. Department of Defense. That funding and additional collaboration with the Maritime Applied Physics Corporation, an engineering company that frequently partners with the U.S. military, helped support the advancement of NS honeycomb technology.

The next phase of assessment will include ballistic testing. The researchers are also building a lab prototype of an enhanced combat helmet with NS honeycomb cells integrated that will be completed this fall.

Source: University of Texas at Austin

Published July 2015

Rate this article

View our terms of use and privacy policy